Sarah Verreault, a student at the University of Leicester’s School of Museum Studies, has completed an audit of the museum’s shoe collection over the past eight weeks. She has chosen the story of British clogs, locally worn and produced, to highlight in a new display at Wakefield Museum.

Learn more about these #cleverclogs in her blog below!

|

| Sarah Verreault with her Clogs display at Wakefield Museum |

What are British clogs?

A British clog has a leather upper, a wood sole, and irons nailed into the heel and sole.

They first appear in written accounts in the 1600s in Lancashire, Cheshire and Cumbria, then spread to the rest of the north of England. They reached peak popularity in the second half of the 19th century. They declined in the first half of the 20th century as other types of shoes became more affordable and fashions changed. Clogs then became a symbol of poverty and charity. Some industries, such as heavy engineering and farming, continued to use clogs. Today, they remain popular for certain kinds of dances such as Morris dancing and clog dancing. Other styles of wooden soled shoes still come in and out of fashion.

Clog making is now on the Heritage Craft Association’s Red List of Endangered Crafts with only five registered full-time makers.

|

| A child's pair of leather clogs, with horseshoe irons on the sole and heel, dating between the 1920-1950s |

How are clogs made?

The leather uppers were made in the same way and styles as other types of shoes. New and old shoes could be clogged to make them more hard-wearing. A pair of uppers could be re-ironed and reclogged many times, so the leather was well cared for.

The clog-block maker would harvest the wood, preferably alder, and cut it into blocks to sell to the clogger. The clogger carved the blocks into a sole. Like other shoes, until the middle of the 19th century, they were made on straight lasts, meaning that the left and right were the same shape. If the clogger was skilled enough, the sole could be fit to the foot of the customer.

Earlier clogs were bound around the edges with hoop-iron. The familiar grooved horseshoe irons became more common in the early 19th century. The local blacksmith or the clogger would fit the irons. Extra protection like iron plates and leather pads could also be added.

|

| A pair of child's clogs, with leather upper and a square upturned toe, dating likely from 1850-1900 |

Where were they worn?

Clogs were particularly present in the north of England and the south of Scotland but do also feature elsewhere. They are well suited to the landscape and weather in this region. Clogs require a special rocking or rolling movement to walk because they are much heavier and stiffer than shoes.They were worn by women and men, adults and children, in the country and cities. They were worn at work and in everyday life including to church. Crimp clogs, called ‘dandy’, ‘Sunday’ or ‘neat’ clogs, would have elaborate designs cut into the upper. Children used to play at making sparks fly by hitting their irons on stone. The wood sole wore through stockings quickly so many people wore clogs bare foot. With or without stockings, they were often lined with straw, hay or bracken.

They were worn in mines, quarries, pits and kilns, in building trades, docks and wharfs, agriculture, transport, brewing, mills and factories. Different styles of uppers were associated with different occupations such as the miner’s blutcher clog whose upper only has two pieces or brewer’s clogs with watertight tongues and very square toes. How long a pair would last depend on who wore them and where. Pit clogs would last a little over a year, but in a mill, they could last 20 years with care.

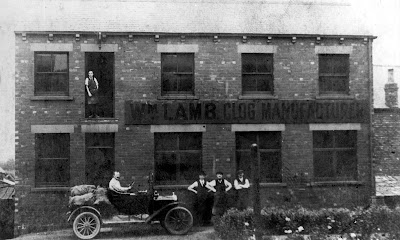

Local Connections: Wm. Lamb Clog Manufacturer

Based in Bottomboat, Stanley, West Yorkshire, the company began in 1887 when William Lamb began producing clogs for miners. It then expanded to supplying shoes for women working in cotton mills. They became one of the biggest British clog manufacturers. |

| Workers stood outside Wm. Lamb Clog Manufacturers' shop, c.1900-1920 |

In the 1920s, the company started making work boots, and army boots during the First and Second World Wars. Later in the century, they manufactured football boots and trainers. Today, they have stopped manufacturing and are focused on importing footwear.

The Clogs - Dress to Impress exhibition is now on display at Wakefield Museum in the main gallery. For opening times and access information, click here

Looking for a soundtrack for your clog-tastic reading? We've put together a Spotify playlist inspired by Sarah's shoe audit here!To learn about another important industries in the Wakefield area, Ossett's shoddy and mungo trade, click here.

No comments:

Post a Comment

We would love your comments - though they may take a day or two to appear.